Building thermography

A thermographic analysis of your building can save you time and money by enhancing energy efficiency. High-resolution thermal imaging with our infrared camera, using wide-angle lenses, ensures fast and comprehensive image analysis in every detail. As a unique advantage, our building thermography display also reveals surface dampness directly. This enables fast localization of mould formation in your building.

This acoenergy service is ideal for practically all building thermography applications:

- Identification of structural defects to assure building quality

- Precise location of roof leakages

- Comprehensive energy surveys

- Easy checking of refrigeration and heating installations

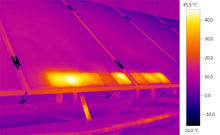

- Monitoring and control of heating systems and solar installations

- Precise localization of pipe bursts

- Investigation of moisture damage

- Prevention of mould formation

- Checking new buildings for air-tightness

- Rapid analysis of building shells Ausführliche Energieberatung durchführen

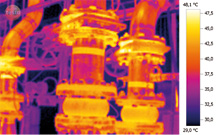

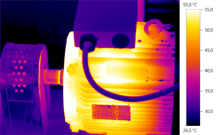

Industrial thermography

Our thermal imaging camera quickly and reliably reveals anomalies and weaknesses in industrial maintenance and production monitoring. All structural materials and components are inspected entirely non-destructively. Potential problems are discovered in good time to prevent failures or fire risk. Thanks to high-resolution thermal imaging, our infrared camera detects even the smallest temperature differences. And documentation is greatly simplified because the built-in digital camera stores an optical image in parallel to the IR image.

This acoenergy service is ideal for practically all industrial thermography applications:

- Regular monitoring of electrical maintenance

- Assistance with preventive mechanical maintenance

- Fast and easy filling level monitoring, e.g. of NH3 separators

- Safe measurement of high temperatures

- More reliable quality assurance and production control

- Security of energy supplies

- Precise identification of critical temperature zones on printed circuit boards

- Quality control of compressor and pump motors

- Monitoring and control of heating systems and solar installations

- Analysis of energy distribution systems

- Inspection management on large production plants

References

Available on request.

You are welcome to contact us for references or a personal appointment: